LIGHT HOUSE PROJECTS - RAJKOT, GUJARAT

TECHNOLOGY : Monolithic Concrete Construction using Tunnel Formwork

|

|

|

|||

|

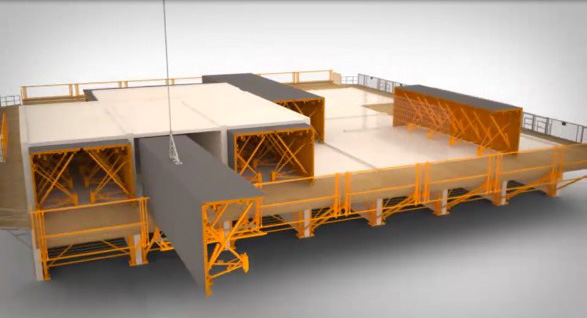

In ‘TunnelForm’ technology, concrete walls and slabs are cast in one go at site giving monolithic structure using high-precision, re-usable, room-sized, Steel forms or moulds called ‘TunnelForm’. An already established System for building construction in many countries, this system intends to replace the conventional RCC Beam-Column structure which uses steel/plywood shuttering. ‘TunnelForm’ system uses customised engineered steel formwork consisting of two half shells which are placed together and then concreting is done to form a room size module. Several such modules make an apartment. Construction Process:

Special Features:

|

||||

> > |

> > |

|||

> > |

> > |

|||

|

Contact Details:

|

||||